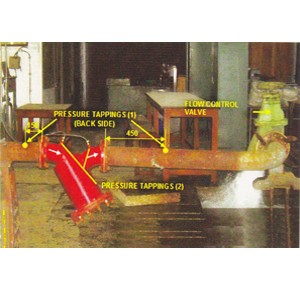

These pipe line strainers are for continuous service. Twin filtration Chambers and integral isolating parallal plug valve per unit servicing without interruption of flow. No possibility of hydrolic shock on charge over. Due to quick release cover no tools required for basket removal and results in a minimum down time. Suitable only for liquids.

b.jpg)

Materials :

Cast lron, Cast Steel, Stainless Steel fitted with stainless steel/mild steel basket. Depending upon the degree of filtration and pressure drop required, the replaceable inserts are fitted.

Application :

These type of Strainers are for continuous service. Double filtration chambers with one isolating valve permits servicing without interruption of flow.

Drilling can be done as per customer's specification

Peessure Rating :

i) Upto 15kg/cm2 for C.l. upto 600C

ii)Upto 45kg/cm2 for Cast Steel/S.S. upto 600C

Standardeessure Rating:

i) ANSI B 16.5 class 250 for C.l.

ii) ANSI B 16.5 class 300 for C.S./S.S.

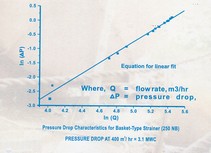

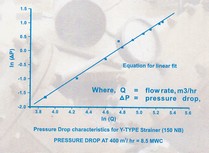

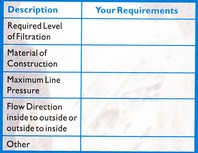

Performance Requirements

Design Features

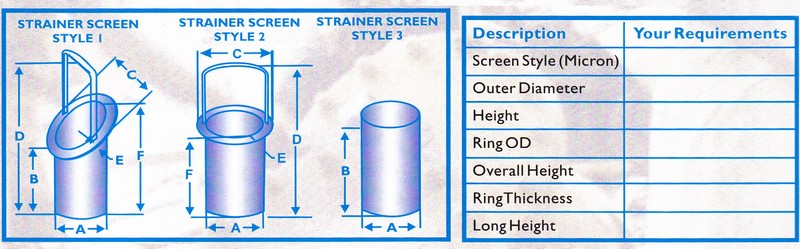

We can supply baskets for all makes of “y” & basket strainers. The range of materials and size of units is unlimited. Using the following materials we can provide screens and baskets suitable for a wide range of applications.

• Perforated Plate

• Mesh or Mesh / perf. Combination

• Wedge Wire

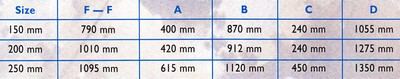

Dimensional Requirements

These large duplex filters employs a simple rugged and positive method for change-over, using two disc valves operated by screwed shafts. The internal screwed portion of the operating shafts are sleeved, totally enclosed and protected from liquid. As standard the operating shafts are interconnected with the help of chain for simultaneous operation and are provided with a valve position indicator showing which chamber in on stream. These filters are also fitted with quick release cover.

Strainers take their name from their configuration. They are typically used in application where the amount of solids to be removed is small, and where frequent clean – out is not required. They are most commonly used in pressurized lines, water or oil, but can also be used in suction.

A Y-Strainer has the advantage of being able to be installed in either a horizontal or vertical position. However, in both cases, the screening element must be on the “downside” of the strainer body so that entrapped solid can be properly collected and held for disposal.

A blow down plug on the drain port will allow clean-out without removal of the screen, and without interrupting the process flow.

Size of the screen as well strainers can be fabricated as per Design requirement.

Features :

Machined, tapered seat ensure a perfect fit for removable, stainless steel screen.

• Covers furnished with blow off tapping

• Heavy gauge perforated stainless steel normally furnished with spot welded seams. For exceptionally fine straining,

perforated screens are lined with wire mesh.